OPINIONS ON FIREARMS & ACTION WORK

Colt – Pietta – Standard Manufacturing – Uberti – U.S. Firearms – Ruger Vaquero

It took some time for me to decide to do this. I don’t want to come off as knowing everything or so full of myself that you should believe without hesitation what I think, this is my opinion. However, after working on three to four hundred guns a year, over 28+ years, you begin to notice the things that matter. This should be helpful to those of you who feel lost in the sea of choices to make fewer mistakes when buying and having your guns worked on. Feel free to call me any time during business hours if you want more information.

I do have some knowledge in this area. I have been working on single action revolvers since 1987 and I have seen almost all of them. From Early 1st Gen Colts to yesterday’s Pietta/Uberti and todays Standard Manufacturing SAA, I have done my share of noticing how well each manufacturer builds their guns and the changes made through the years. I have worked on just about every Single Action Army or 1800’s Reproduction ever made.

There are twelve areas I feel are important to look at when making a decision in buying a firearm. I don’t list cost because it can impair good judgment. Here are the areas I feel are important to be considered;

1. Quality of the metal used.

2. Machined quality of internal parts.

3. Fitting tolerances of the internal parts.

4. Hardness of internal parts.

5. Machined quality of the frame, barrel and grip frame.

6. Internal machining of the frame.

7. Overall assembled fit and finish of the firearm.

8. Functional durability relative to application.

9. Initial timing of the firearm.

10. Quality of the finish.

11. Safety.

12. Ease of maintenance.

Italian Revolvers

Considering they all come from two factories, Pietta and Uberti, you should know they are not all the same. The two factories have different machining capabilities. Each importer, (Cimarron, Taylor’s, Cabela’s, EMF, Dixie Gun Works, etc.) also has different specifications for each model. The quality of the product depends how the firearm was “Spec’d” and on who is checking to make sure those specifications are being upheld. I am talking about engineering specifications. From the type of steel used to the hardness of the trigger to the precise dimensions of the hand. Quality control personnel overseas and in the US are the key. I am not fond of Italian models that have internal safety mechanisms in the hammer, retractable firing pins, transfer bars or finishes that look like black spray paint. Call me and I’ll explain. “Four clickers” take some getting used to if you are new to single action revolvers. All Uberti made revolvers now have a retractable firing pin in the hammer and only three clicks unless you buy the Old Model black powder frame. All Pietta made revolvers are still four click Colt Replicas. Price and quality go hand in hand with Italian revolvers.

The production of Italian revolvers has never been very consistent. I have seen the machining and parts fitting vary a lot over the years. There just seems to be an ebb and flow in quality with Pietta and Uberti revolvers. Some years Pietta has better quality, some years Uberti has better quality. It is the small things I’m talking about. For the most part they both make quality revolvers for the money.

Cimarron F.A. The Model P – Made by Uberti. “Pre-War” & “Old Model”. The “Pre-War” model has the retractable firing pin in the hammer and a three click action. These have a wide notch rear sight and squared front sight. The retractable firing pin does create reliability issues in the competitive setting. Many shooters have had problems with these. Fitting a standard hammer and trigger converts these to a regular 4-click action. The “Old Model” has the black powder frame with the single screw that holds the base pin in the frame. The Old Model, black powder frame, does not have the retractable firing pin safety in the hammer and has the four click authentic action. However it does have a V-groove rear sight and a “pinched” front blade just like an original early 1st Gen Colt. On both of these the bluing is deep and the case coloring is attractive on most of them. If you are going to dry fire hundreds of times a week and shoot every week-end, expect to replace some parts from time to time. Have a set of SAA screw drivers. Clean, oil internals lightly and snug the screws regularly.

Model P, 45LC, 4 3/4 weighs 2.15 lbs.

NOTE: The new (2017-Present) Cimarron Model P “Pre-War” with the cross pin frame has the floating firing pin in the hammer. This is a three click action because there is not a “safety” notch anymore. No longer an authentic replica. Some will love it, some will hate it, some won’t care.

Cimarron F.A. The Frontier. Made by Pietta. These are a nice Colt SAA replica with an authentic four click action. It also has the 1st Gen Colt beveled cylinder detail. This model has the cross pin latch that holds the base pin in. It uses a coil spring and plunger on the hand for reliability. This gun has a natural balance that just feels great in the hand. It shares being the lightest with Great Western II, as they are essentially the same revolver with a different name. These have a wide notch rear sight and a squared front blade. The bluing is deep and the case coloring is attractive on most of them. If you are going to dry fire hundreds of times a week and shoot every week-end, expect to replace some parts from time to time. Have a set of SAA screw drivers. Clean, oil lightly and snug the screws regularly.

Frontier, 45LC, 4 3/4 weighs 2.15 lbs.

Taylor’s & Co. The Smoke Wagon. These are made by Uberti and have the retractable firing pin in the hammer and a three click action. They have a wide notch rear sight and a squared front blade as well as a coil spring for the hand. The bluing is deep and the case coloring is attractive on most of them. The retractable firing pin does create reliability issues in the competitive setting. Many Mounted shooters have had problems with these. Fitting a standard hammer with a new trigger fixes this. If you are going to dry fire hundreds of times a week and shoot every week-end, expect to replace some parts from time to time. Have a set of SAA screw drivers. Clean, oil lightly and snug the screws regularly.

Smoke Wagon, 45LC, 4 3/4 weighs 2.25 lbs.

EMF-Company. The Great Western II Californian. Made by Pietta. These are a nice Colt SAA replica with an authentic four click action. It is also shares being the lightest of the single actions with the Frontier. This gun has a natural balance that just feels great in the hand. It has a wide rear sight notch and a squared front blade. It has a coil spring and plunger on the hand for reliability. It is the exact same revolver as the Pietta Frontier with different stamping on the barrel. The bluing is deep and the case coloring is attractive on most of them. If you are going to dry fire hundreds of times a week and shoot every week-end, expect to replace some parts from time to time. Have a set of SAA screw drivers. Clean, oil lightly and snug the screws regularly.

Californian, 45LC, 4 3/4 weighs 2.15 lbs.

American Made Revolvers

Colt, Ruger®, Standard Manufacturing & US Firearms. I’ll make this short and sweet. If you want more information feel free to call me anytime during business hours.

Colt Single Action Army. The Third Generation Colt SAA from 2005 to present is the finest Single Action Army Colt has ever made. These are gorgeous revolvers that are well worth the invesment. Internal machining is clean and the fitting of parts is exceptional. The metal prep and fitting before bluing and case hardening are very nice. Colt uses a proprietary system for their case hardening that produces the unique colors they have. Much nicer than Italian revolvers. More importantly because Colt uses the right alloys in their revolvers and the hardening of all parts is perfect. No other Single Action revolver on the planet is as durable because of this. I back that statement up with over twenty eight years of working on Single Action revolvers. There is a reason why they are in such demand and it is not hype, it is quality and history. Bluing and case hardening are done in-house. Like all single action revolvers, keep them clean as they can be finicky when they get really dirty. The screws on Colt revolvers are harder than on any other SAA revolver made. The little red washers that keep the screws from backing out help immensely. Hold a late 3rd Gen. Colt in your hands, eyes closed, and you can tell it from every other SAA revolver made. Colt SAA 45LC, 4 3/4 weighs 2.30lbs

Final Notes: Colt’s customer service is second to none. Colts are collectable and have an American history that is hard to resist. Get a hold of a 2nd Gen if you want an investment that will deliver a good return. They are starting to rise in value. Colts customer service is second to none. You only need to own one Colt to know you have the best.

Ruger®. Old Vaquero and New Vaquero, They are tough. Case in Point: In 2009 I worked on a pair of Vaqueros that were used by a noted National Champion. He later professed he had not cleaned the guns since he bought them, …three years earlier! I have pictures of the inside of his guns that would make you fall out of your chair. The guns still worked, I did notice the actions were gritty and not too smooth. There were blades of black oily grass sticking out of the trigger slots, so I opened them up to clean them. It was like a potato farm. Again they still worked with all the crud in them, just not very smoothly. No other gun would do this, period.

There are only two ways to damage a Vaquero. (Pronounced; Va-care-o, by Gringos, or in Spanish, By-care-o)

1. Let someone work on it that is not a qualified gunsmith.

2. 3oz of C4.

Old Vaquero. Slightly larger than a Colt SAA or Italian clones. They are built like the WWII 1911. It has loose tolerances built into the design in order to function under the harshest conditions. It is safe with six rounds loaded. The Old Vaquero has a larger grip frame that provides 1/8 inch more room for your middle finger behind the trigger guard. The grip is also longer at the bottom, more room for your little finger. They are making a come-back.

New Vaquero. Just about the same size as a Colt SAA. They have a unique “index pawl” that when removed allows the real “pawl” to freespin the gun. They have the cresent ejector and Colt style base pin that the Old Vaquero doesn’t. The hammer spur is higher than the Old Vaquero or Colt. Many people change these out for the Super Blackhawk hammer which is low and wide or the Old Vaquero hammer/New Model Blackhawk for the original look. The Talo edition New Vaquero has the Old Vaquero hammer in it, go figure. Competent gunsmiths should have the Old Vaquero/New Model Blackhawk and Super Blackhawk hammers in stock if you want to change yours out.

New Vaquero 45LC, 4 3/4 weighs 2.35lbs.

Final Notes: It loads without cocking the hammer. It is safe to load six rounds into. They are a bit tricky to take fully apart and re-assemble. Transfer bars break, on rare occasion. Well made, durable revolver. Heavy, gritty actions out of the box.

** Some of the New Vaqueros with the serial numbers starting with 513-XXXX have cylinder chambers not reamed deep enough. Unless the shells have been sized they will not go all the way into the chambers. This is an issue for Cowboy Fast Draw shells only. You need to have the chambers reamed deeper so your shells will work in these revolvers. I charge $45 to ream the chambers deeper.

Standard Manufacturing. The quality of fit and finish very nice. The frames are charcoal case hardened and have great color. The bluing is deep and dark. They use a 1st generation Colt style firing pin and hand. All screws are qualified, pointing in the same direction, even the grip screw. All screws are fire blued along with the base pin, trigger and the ejector. As far as size comparison they are so close to a 3rd Gen Colt it doesn’t matter. We are talking a couple of thousandths of an inch. Like all single action revolvers that roll off the assembly line, they have heavy and rough actions. With quality action work done, they are much more plesurable to shoot.

Some customers, including myself, have had quality control issues. The hands are not hardened (Colts are) and will cause timing issues with extended or hard use. Cylinders over-rotating due to overly tight fitted bolts. Hammers that bind in the frame because the hammers are too wide for the frame slot, (US1091). Some have even been found with Italian (Uberti) hands in them, no kidding. Three revolvers I received had Uberti, Model P hands in them. US901, US850, US843 all had Italian hands in them when I received them. Standard promply sent me new hands without comment. I have detailed photographs showing all of these issues. If you want to know if yours has an Italian hand in it, send me an email and I will show you what they look like.

All revolvers that were sold by me have the correct parts in them and function perfectly.

Final Notes: I stopped selling these revolvers because their customer service was less than friendly. Qualified screws will make you nuts as they go more out of time every time you touch them. I have taken a lot of heat for being honest about these revolvers. They don’t put Italian hands in them any more…….I guess what I say matters. You’re welcome. Don’t shoot the messenger.

Standard Manufacturing Single Action, 5 1/2, 45LC weighs 2.25lbs.

U.S. Firearms. Single Action was one of the finest Single Actions ever made, after serial number 22500. What a shame though as we will never see them made again. This gun was made on state-of-the-art CNC equipment in Hartford Connecticut. Truly a work of art and for the most part an exact copy of a late 1st generation Colt. They were made using the blue prints from 1Gen, 2nd and 3rd gen Colts. They are NOT a reverse engineered Uberti. Those were the early guns when the company was getting started. They took the best features of each Colt generation and created this firearm. This is fact supported by conversations with two of the original employees of the company and speaking with Doug Donnelly in person. The metallurgy, machining, fitting of parts and final finish of these guns is outstanding. I sold hundreds of these and they were all without flaw. They are incredibly well made, durable and can be dry fired ’till the end of time because of the 1st Gen firing pin. I keep a library of part dimensions on all Single Action models. US Firearms parts are the same to within 0.005″, that’s five thousandths of an inch! People who own them don’t hardly ever want to sell them. They sure are going for a pretty penny now!

USFA 45LC, 4 3/4 weighs 2.30lbs

Final Notes: The Rodeo is the exact same gun with a different finish. US Firearms was the only production SAA on the market that was charcoal and bone case hardened on the frames. (Turnbull Restorations did them all) All Italian manufacturers use a salt/chemical treatment, AKA “case coloring”.

** I have notes, photos and serial numbers to help you identify; 1. All Uberti parts. 2. Uberti parts in US frame. 3. 100% US made. Around s/n 22000 is when they started the big change to all US made. There are some mixed parts revolvers from 22000 to 22500. It is usually just the ejector rod housing.

Action Work

Quality action work will make your revolver more accurate, last longer and be more enjoyable to shoot. By the same token don’t let someone work on your gun that is not qualified. I have seen some pretty bad butcher jobs done by a “friend or machinist that works on guns”. Don’t do it. You wouldn’t let me rebuild the motor in your car just because I’ve been a gunsmith for 28 years. It takes ten to twenty years to learn all the intricacies of all the revolver models. It takes ten to twenty years to aquire the skill set to be proficiant. Quality action work keeps the gun from wearing out as fast and increases accuracy considerably. A lighter mainspring is essential to saving the trigger sear and having more accurate shots. I have fixed (TIG welded) or replaced hundreds of triggers and hammers that have been worn out by heavy flat, original mainsprings. Get those stagecoach springs out of there if you want your guns to last! Internal parts need to be reshaped slightly to reduce pressure on mating parts as the gun is cycled. Polishing should be done to specific areas and NOT everywhere like some big box companies do. This just makes the internals sloppy and they will wear out faster. Advancing the timing is also a short cut to to keeping a revolver from over-rotating. This creates more problems down the road. Like damaging your cylinder. Proper shaping of the bolt will produce superior results. Quality gunsmiths use precision tools to shape, align and fit parts within 0.005 of an inch.

I have fixed a lot guns where all or some of the springs were ground or bent. This destroys the molecular structure of the metal in both cases. This leads to progressive softening and early failure of the springs. You will also get inconsistent results from gun to gun. Before you have action work done ask if they are going to grind and bend your original springs or install new custom springs. Flat mainsprings can be ground, but if not done properly, they will fail or fatgue. Idealy you want new, custom made springs. Coil mainsprings should never be ground. Quality gunsmiths will install “purpose designed”, manufactured springs of a precise resistance. We will inspect, de-bur, cut new angles, hone and polish internal areas that have “friction load”. This produces consistent action work that is reliable and durable, but most of all the firearm will perform better and last longer. Grinding and bending factory springs is a cheap way to do action work that results in inconsistent spring rates and early failure. Quality gunsmiths will provide you with high quality new parts that are designed to give you flawless and matched performance. Quality action work is extremely beneficial to your firearms’ longevity and your shooting skills.

There is a debate over the use of flat bolt/sear springs versus wire bolt/sear springs. I feel the need to comment about this. There is published “opinion” in shop manuals that flat springs are superior. It is stated that, “wire springs tend to take on set early and weaken faster…”. I emphatically disagree. These manuals were printed in the 1950s. We are in the 21st century now and high carbon wire spring steel is available. When shaped properly, they simply don’t wear out. I have numerous State, National and World Champion SASS, CFDA and Mounted shooters that use me exclusively for their gunsmith needs. Some of them brought me revolvers with fatigued flat springs that were causing over rotation and some of them brought me revolvers with broken flat springs. Most of these springs had been “tuned” by a professional gunsmith. One of these top shooters was very reluctent to let me use my wire srings as he had heard from a noted gunsmith that wire springs were inferior. It was 2008 when I did the action work on the first two of six of his Colts. Over the years he has worn out the bolts, the hands and most recently the cylinders on two of them. The springs I made and installed are still in perfect working order. He has cycled these revolvers hundreds of thousands of times at incredible speed. He claims more than 500,000 times. I have easily replaced over 100 broken or fatigued flat bolt/sear springs in the past 15 years. I have customers, that are not competitors, that still insist on flat springs. I have no issue with using flat springs when the customer requests it. They are altered as specified in the foremost Colt Shop Manual.

I make my wire springs using the highest quality 1080 high carbon spring steel. I use four different gauges of wire depending on the sound and smoothness the customer wants. The springs are bent on a jig I made that limits the stress on the wire as they are formed. The longevity of the springs is due in part to how I make them, but also due to the internal shaping and honing of the parts associated with these springs. It is my opinion and experience that wire bolt/sear springs, made properly, are superior to flat springs in every way.

Factory mainsprings are also a serious problem.

Below are two pictures of what happens when you keep the heavy factory mainspring in your Single Action Revolver. The gun these parts came from was only one year old. The hammer and trigger sears are destroyed. The bottom lobe on the hammer has been completely rounded over and is unsafe and the trigger is ruined. In order to make this gun safe and function properly you would need to buy a new hammer, $180-$250 or the bottom hammer lobe has to be welded and re-cut, ($175), a new trigger also has to be fit, ($75).

Quality action work would have saved both these parts.

The extreme pressure from the factory mainspring has worn the tip of the left trigger completely off.

Front hammer is new. Notice the trigger sear notch rounded off on the rear hammer.

Cleaning Your Guns

I’m not talking about the barrel and the cylinder. If you shoot competitively or every weekend for fun, I highly recommend that every year you completely disassemble your guns and thoroughly clean all the internals. Pick a date and do it. Dirt and dust, are the main culprits. They will start to act like sand paper on the internals. Oil attracts dirt. Grease is worse. This causes wear on all the friction surfaces. Parts with tight tolerances become sloppy and the timing will begin to go south. Trigger sears wear out and hammer notches wear down. See “Early Bolt Timing” below for example. I offer a gun cleaning service for a nominal fee of $75 per gun. This is total disassembly, solvent cleaning with brushes, checking for wear, oiling, greasing and re-assembly. Do not Sonic clean your guns! I don’t know how this caught on in Mounted Shooting, but I get a lot of rusted malfunctioning revolvers from this sport. Yes even the stainless guns. They are made of 316 stainless and it rusts.

The two pictures below are from guns used by a local competitive shooter. He “cleans” his guns after every shooting event. Three to four times a year he sprays cleaner inside the hammer and trigger openings and then blows them out with compressed air. As you can see that didn’t work too well. You really have to take them apart to get to the dirt.

Check Your Bolt’s Timing

Unload the firearm. Hold it in your right hand, upside down with the barrel pointed to your left and the hammer to the floor, at eye level. Slowly cycle the hammer and watch as the bolt pulls away, out of the cylinder notch. The cylinder spins and the bolt should pop back up on the cylinders lead, aka advance, right before the notch. (Call it the “lead” call it the “advance”, tomato/tomäto) Take note of where it hits. Late is better because there is metal to work with. Early drop, before the lead, usually means the bolt or hammer cam is worn out. Late drop usually means it needs to be tuned properly. A properly fitted bolt will drop fully in the lead. The crowning of the bolt is also critical when the action is cycled fast. They are usually not correct from the factory.

Late Bolt Timing

The bolt drops late and strikes the front edge of the cylinder notch. This will cause the front edge of the cylinder notch to become crushed (Fig. 1) and eventually result in the cylinder not locking up properly. This can be fixed with minor gunsmith work.

Early Bolt Timing

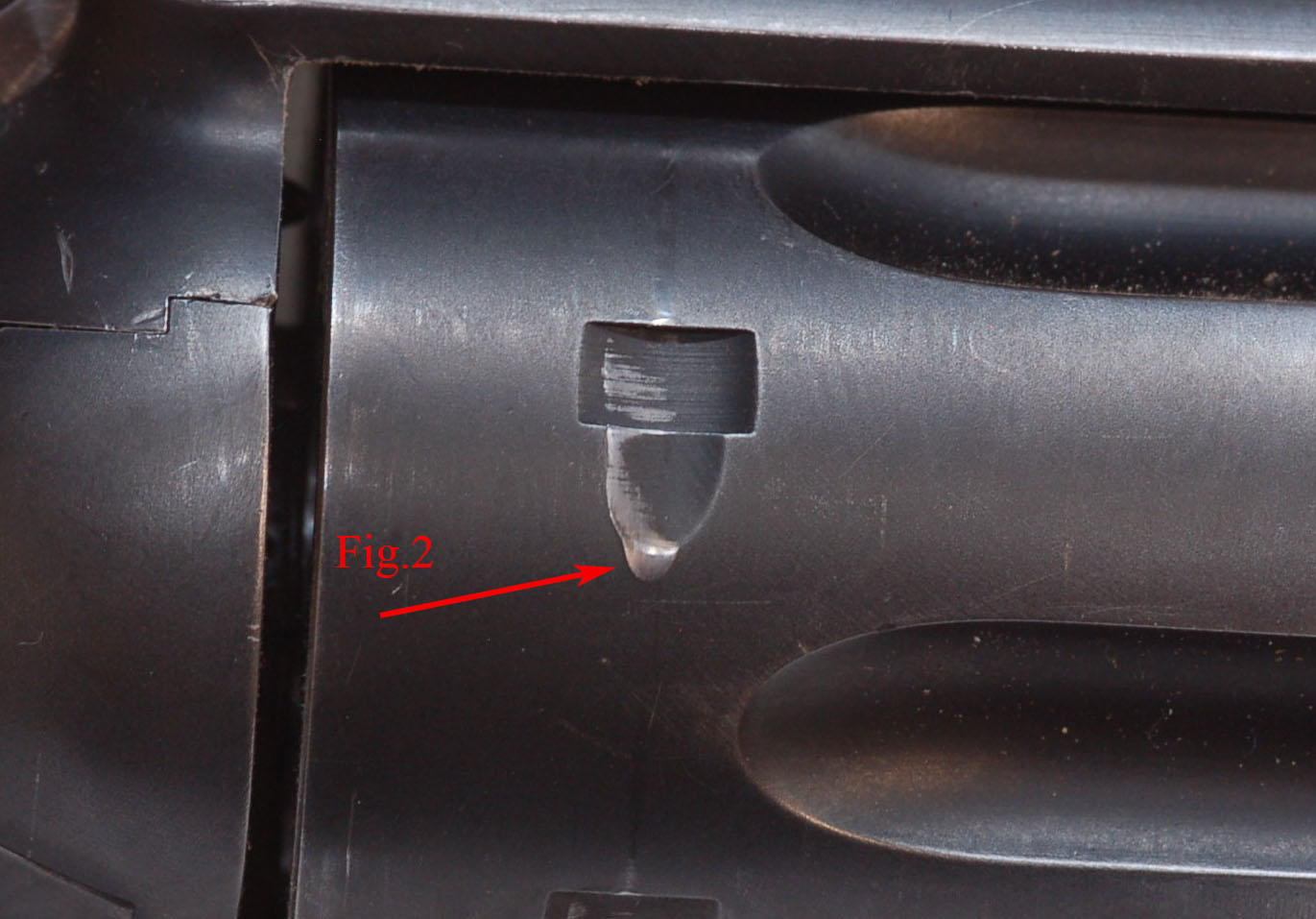

This photo shows the damage from worn bolt leg. It is falling on the cylinder and not in the lead (fig 2). The bolt head was also crowned off center and is not riding in the center of the lead. Very common. This gun needs a new bolt.

This photo shows the bolt where it would be falling late. It is partially in the bolt notch. The bolt needs to be fit properly.

A properly fitted bolt should fall mostly in the lead or fully in it. This photo shows the bolt falling early in front of the lead and getting close to needing replacement. See Fig. 2 above.

Single Action Revolver Safety and Handling

There are usually four audible “clicks” when cocking the hammer on a Single Action revolver.

1. The first notch (1st click) is commonly called the “safety notch”. In the late 1800’s it was common practice for the U.S. Army to carry a single action revolver with six rounds and the trigger in the “safety” notch. However, this is not considered a “safety” now days. This notch is fragile and could break if the firearm was dropped on the hammer. This could cause the revolver to fire. There are no known incidents of this happening, but it doesn’t mean it can’t happen. Some people carry a single action revolver with six rounds loaded and the hammer in this “safety” notch. This is not recommended, at all, ever! Pulling hard on the trigger when it is in this notch will bend or break the notch and/or the trigger.

2. The second notch, (2nd click) is the “Loading Notch”. The firearm can be loaded when the hammer is in this position. Load one cartridge, skip a chamber, then load the remaining four cartridges. Immediately cock the hammer all the way back and then let it down very softly. You will be on the empty chamber. After firing all FIVE rounds, pull the hammer to the second notch (2nd click) and use the ejector rod to eject the spent casings. When all casings are ejected, cock the hammer all the way back and then let the hammer down very slowly. NEVER let the hammer down from the loading notch. If you let the hammer down from the loading notch and not the “Full Cock”, you will scar the outside of the cylinder as the gun is now out of time. Always pull the hammer all the way back and then let it down. Pulling hard on the trigger when it is in the loading notch will bend or break the notch and/or the trigger.

3. The third “click” is not a notch. This is the sound of the bolt snapping up and hitting the cylinder in the “lead” groove. The bolt will ride in lead as the hammer is pulled farther back and then will pop into the “cylinder notch”.

4. The fourth click is the sound of the trigger falling over the hammer sear on the hammer and simultaneously the bolt dropping into the notch on the cylinder. The firearm is now ready to fire. Pulling the trigger will cause the firearm to discharge. There is NO SAFETY when the hammer is pulled all the way back. Never pull the hammer to this position when the gun is loaded unless you intend to fire the firearm. If you wish to not fire the gun when the hammer is fully back, you must proceed with extreme caution. Point the firearm in a safe direction. Lower the hammer all the way down, very carefully, as you will now place the firing pin directly on a primer of a live cartridge. Now pull the hammer to the second notch (click) and proceed to unload the firearm or rotate the cylinder until it is one chamber from the empty chamber and then proceed to cock all the way and then let the hammer down on this empty chamber. Some people lower the hammer to the “safety notch” from full cock, don’t do this. Many Colt and Replica revolvers will lock up if you do this because the bolt leg has not re-set over the hammer cam.

5. You can hear five clicks on many revolvers if you cock them very slowly. This is not always a bad thing. It can mean the trigger is short and you need a new one. You need to call me if your revolver has five clicks or the trigger pops forward way before the bolt locks into the cylinder notch.

LOAD ONE SKIP ONE

The safe way to load a single action revolver

Load one cartridge, skip one chamber and then load four more. Now fully cock the hammer all the way back and let it down slow and easy. The hammer will be resting on an empty chamber.

It is a good idea to buy five “dummy” cartridges and practice the loading and unloading of a single action revolver if you have never handled one before.